China investment Conference Shanghai 2016

The European chamber of commerce invited on September the 26th a great number of representatives of companies active in the Chinese market, to discuss the best approaches on investment for the following years.

Numerous speakers have given their own insights on the matter at hand, and have given their own suggestions on how to approach the ever-changing Chinese market.

First speaker: Mr. Michael Seitz

After the usual opening remarks, the conference started promptly with the introduction of the research prepared by KPMG advisory, regarding the Global Manufacturing Outlook in China.

The research focused mostly on the areas where the manufacture industries were competing for growth and how prioritized the research and development of innovations were held in their plans for growth.

Growth the next 2 years was seen as a high priority by the 74% of the interviewed companies, and as strategy for such growth, the most popular approach was to enter new geographical markets, with China and India in the lead with a combined 56% of companies.

Another relevant sector, which was held in high regard, was the development of new R&D offices with organic investments.

As the competition is these two countries is considered very high, there is a need for most of the companies (56%) to increase investments steadily in China and India in the following years.

At the same time, Chinese companies are pursuing the export of even more products, and are switching their focus toward new markets, especially India and Africa.

Main concerns for companies operating in China in the following years are economy disruption, market disruption and supply chain disruption. For this reasons the main are for investments are IoT, or internet of things, to allow supply chains to became more technologically advances and increase the production of products.

In order to control then the market, several steps can be taken by companies:

- Map and adapt their products

- Create the right relationships

- Develop partnerships

- Increase R&D development

- Focus investments on the Chinese market [as to improve the technology in use in the factories]

Second speaker: Mr. Clas Neumann

Once the steps for companies have been clearly defined, the focus moved more on the digital transformation in the IoT industry.

Right now, especially in the manufacturing business, factories are pushing toward new innovation in this digital world.

As the market is filled with customer centricity, the industrialized products are making more and more decisions based on data. One clear example is the agricultural business of today, like the one we can experience in Germany; we can see how the farms of today are more digital than ever. Where most of the automated task are connected to a central computer, which makes most of the routine decisions.

The future holds only good prospects for China in this new era of digitalization, as China is to become the world largest R&D investor for 2020.

In addition, China and the new plan for “Made in China 2025”, is focusing more and more on consolidating the country’s name as the producer of reliable products and new technology.

This can also be see in the new developments in IP regulations, and the need to strengthening the laws, as suggested by the Chinese prime minister, as high R&D generates high IP risks.

Third speaker: Mr. Reto Bless

On the same topic of new development for factories with IoT technology, and the desire for China to pursue the “Made in China 2025” plan, the focus was moved on the Industry 4.0, the new name for what is believe the new industrial revolution of the 21st century.

It was explained how technology and its influence on the Chinese Smart Factory landscape works.

New advancement in technology brings a natural evolution on the manufacturing processes, a central control of the factories brings a growth in production, and the reduction of labor force required operating the machines.

What is needed now is a standardization of the requirements for this new technologies and an understanding on how to manage the new complexity, as well as how to have the best infrastructure to support the new connectivity for this digital innovations.

Closely at the same time has to go the design of the new robots and machines utilized in the factories and the training for the new labor force required operating such factories.

To achieve the best results there has to be a good combination of trained people, standardized processes and new technologies.

Fifth speaker: Larry Y.Ho

How can then China develop their factories to be successful in this new industrial revolution and what are China IoT opportunities?

IoT is regarded as the future of industrialization, and is a great part of the Industry 4.0 campaign, it is considered the way to go to adapt production line as much as possible to the products itself.

To complete the passage from the Industry 3.0 and Industry 4.0, different steps have to be taken, especially regarding the automation of the environment, incorporation of Robotics and the delivery of data in a more direct and secure way.

The only setback now, is the lack of a standardization in the innovation of the manufacturing line and production line, as such, many companies follow different standards and productions are very different from one another, as well as the software utilized.

The various areas of difference are mostly on electro-mechanical design of robots, machines utilized, packaging and assembly line orders, and IoT embedded system engagement, as well as the development of proper software to be connected with the new innovative hardware.

Other Speakers: Mr. Laurence Barron, Mr. Jean-Claude Zhang

With a more clear idea in mind about the new Industry 4.0, the focus of the event switched toward some case studies of companies developing new products in this new digital revolution.

We assisted to the presentation of Market for the Market about Airbus Group China, a very long-standing successful company in China that has been operating for more than 30 years. Innovation is part of the whole business plan of the company for decades, as any new plane has to be developed with the latest technologies.

In addition, we had a presentation about new mobility services, or NMS, which are flooding the digital market in the last years here in China. Principally we discussed about car sharing and car transport services in Tier 1 cities, which will potentially replace the need for everyone to own a car, and as such reduce pollution in bigger cities.

Seventh speaker: Wallace Bie

After hearing about more practical case studies, the focus moved again back to the Industry 4.0, and the rising of robotics in China.

With the support of a representative of COMAU, Consorsio Macchine Utensili, we traveled into the topic of robotics and the use we do of robots in the production lines, and how the new IoT approach is helping in modifying the manufacturing line.

At the moment China’s industrial robot, density is below average, but has a high chance of growth, and we reviewed market data and trends for the future of Chinese robotics.

We learned that more than 600 companies in China are now producing robots, and for this reason the competition and development of innovation is very high, all this is in line with the “Made in China 2025” plan from the government, which is providing huge capitals for R&D developments in the field.

In addition, the government itself is regulating the robotics industries, thanks to the national robot testing and assessment center. At the same time, Chinese capitals are used to purchase high quality European brands, to acquire patents and trademarks in the field.

All this, is because most people believe that the future of the manufacturing business needs robots easy to use, collaborative and mobile in order to produce real innovative products.

Other speakers: Focus on HR

The focus now switched more on how to select the correct employee to push a company forward, in this high competitive market.

As there is a big change in demand for core work-related skills, the main point for the future should be to rescale supply and demand for jobs, supporting new workers to acquire the relevant skills to be integrated in this new industrial revolution, skill that are not yet accessible to all levels of education.

We moved on with the demonstration of a list of Key recommendations for general management:

How to develop an agile business:

- Strategy:

- Inclusive / bottom up / Stakeholder Involvement

- Align workforce / planning with innovation strategy

- Communicate changes

- Culture:

- Personal & Responsive

- Entrepreneurship & achievement orientation

- Failure culture

- Structure:

- Shorter time horizon

- Change management

- Involve HR as business partner

- Design thinking, SCRUM, Cross-function project management

How to support the development of an agile business:

- Leadership

- Get involved in the early phase of business planning

- Align competency needs with business

- Support development of agile management tools

- Attract

- Fluid organizations / alternative modes of employment

- Bottom-up development rather than lateral recruitment

- Partner with select institutions

- Assess

- Hire slowly and fire fast

- Apply a multi-tool assessment to cover all fit elements

- Emphasize transfer skills rather than technical skills

- Develop

- Pareto: invest in key skills development

- Action driven blended learning

- Offer structured career programs for Young Professionals

Beside the above-mentioned points, another way to properly recruit the workforce of industry 4.0 is to use the predictive Index, or behavioral analysis index. Which is considered a reliable way to assess the culture and reliability of new potential employees.

Last Speaker: Mr. Federico Bonotto

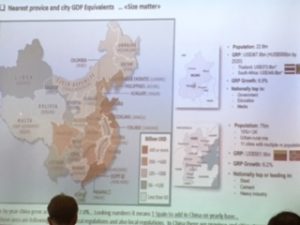

The focus of the last speaker was more on the development of new businesses in China, and the explanation of how new companies that would like to set up offices and factories in China can assess the developments zones given by the government, and what kind of concessions and facilitation they provide.

New companies should choose well the right location, “New development zones” which are very focused on improving themselves, or “2.0/3.0 Industrialized zones” which are already very rich and can invest their own money in developing and supporting new businesses. Understand the need to fix a contract with LOCAL government, considering that 4-6 months will be necessary to achieve a good deal. Decide for a higher registered capital, which will be the key to achieve better conditions and good deals with the government, as well as better concessions. Use the initial capital injection of 15% to setup all the company’s SOP operations. During tax holiday period, start to work on High Tech Economic Status, which requires the development of ? real invention patents or 10/13 improvement patents.

In addition, to receive more local subsidies, it always recommended to companies to move to China part of their R&D offices.

By Federico Bartolini

If you would like some more personalized review of the event from us, please kindly let us know by writing to: public.relation@hongfanglaw.com. Thank you.